Nature’s Operating Instructions

What happens when seven biomimicry teams compete for $100,000 to revolutionize the planet’s food systems?

Photo courtesy of the Biomimicry Institute

After reading Paul Hawken’s The Ecology of Commerce, Georgia carpet baron and industrial engineer Ray C. Anderson challenged his company, Interface Carpets, to eliminate its negative impacts on the environment. This was in 1994. Before he died in 2011, Anderson had more than halved his enormous company’s footprint, largely by promoting free-lay carpet tiles—patterns and installations inspired by the random patterning and variable coloring of the forest floor. Installing carpet tiles in the ground’s image, Anderson found, resulted in less waste and eradicated the need for dyes and traditional glue adhesives.

Biomimicry—from the Greek bios for “life” and mimesis, meaning “to imitate”—is the practice of emulating strategies of the earth’s other 30 million plant and animal species. It is the belief that the natural world’s various biological successes exist as models of innovation that inspire scientists and designers across the world.

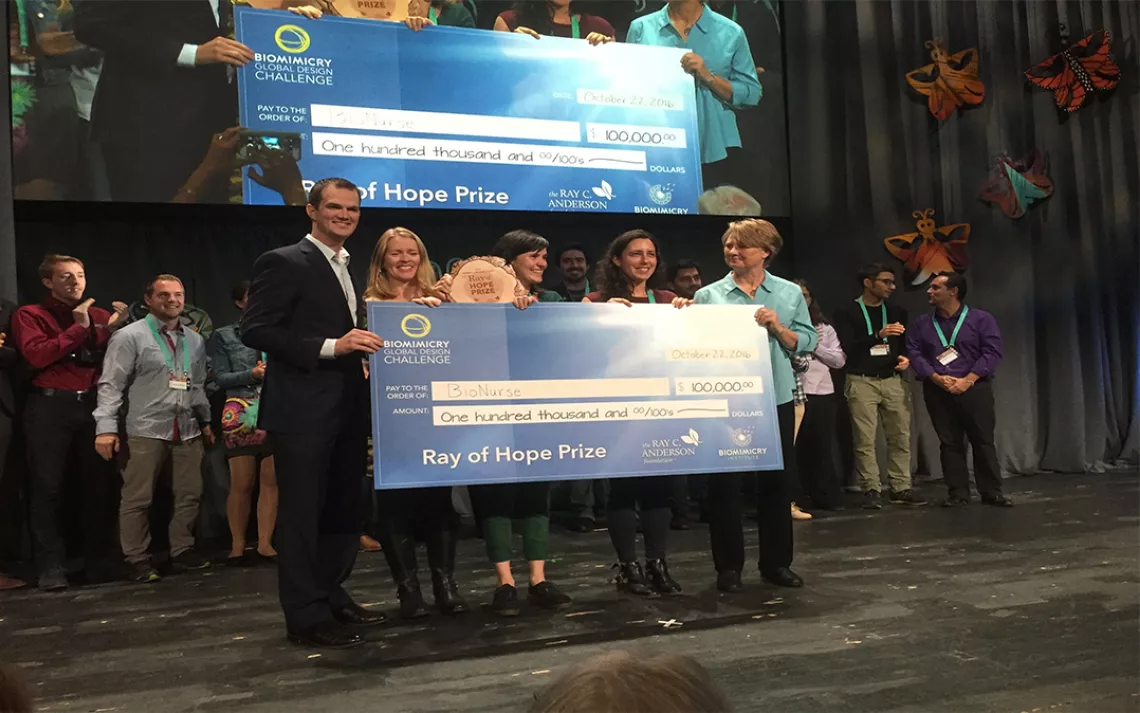

After Anderson’s death in 2011, his family established the Ray C. Anderson Foundation to perpetuate his mission of “industrial ecology”—of businesses doing well by doing good. In 2014, the Foundation joined forces with the Biomimicry Institute’s Biomimicry Global Design Challenge. The inaugural competition, which challenged innovators to look for nature-based solutions to improve food systems, brought forth hundreds of biomimics with ideas to address food waste, packaging issues, agricultural pest management, food distribution, energy use, hunger, and more. In 2015, seven finalists were selected to prototype their ideas, with support from the Biomimicry Institute.

The Challenge culminated at last month’s Bioneers Conference, an annual meeting of social and scientific innovators in San Rafael, California. The teams convened in the Bay Area and pitched their prototypes and financial plans to a panel of judges—biologists, business leaders, designers, and entrepreneurs—all vying for the inaugural Ray of Hope Prize of $100,000. Executive director of the foundation, Ray C. Anderson’s grandson, John Lanier, announced the winners at a packed auditorium of “bioneers”: biomimicry enthusiasts and potential investors.

Read on to meet these radical innovators—and to find out what the future holds for our food systems.

Hexagro “Living Farming Tree”: A group of designers and engineers hailing from Italy, Costa Rica, and Spain, “Team Hexagro” met in school in Milan, where they began the conversation about ways to grow healthy food in tight indoor urban spaces—as well as in refugee shelters, prisons, and natural-disaster relief centers. Their resulting Living Farming Tree prototype is a self-sustaining growing system that doesn’t require soil, but rather comes equipped with “nutrient solutions” that aspirate inside the farming modules, where organic crops grow hydroponically. Team member Felipe Hernandez describes Hexagro as an “easy-to-use, high-yield” product that also boosts economic development and community. How? Users will be connected via an online platform. “Whatever you don’t consume, you can sell,” he says. “Users will quickly be able to recoup costs for the system and then scale up to grow more using expansion sets.” The smartphone app also keeps track of Hexagro’s condition, and will alert users if, say, the system’s lighting mechanisms have gone out. “We’re trying to digitalize farming and make it very easy so we can generate interest among busy young professionals living in dense cities who seek a healthier lifestyle,” Hernandez says.

As for the biomimicry factor, Hexagro’s system borrows from honey-bee hives. Hernandez explains, ”Bees generate various patterns to reduce the amount of material used, which results in maximum diversity with minimum inventory.” Plus, hives’ three-dimensional hexagonal structure has transferred to a good-looking product—very important for a 20-cubic-meter system you have to install indoors. “We wanted it to look like a lamp, a garden, and a fountain all in one product,” says Hernandez, whose team’s project and business model is moving forward, thanks to a Milanese start-up incubator. The team also took design inspiration from guanacaste trees, characterized by fast growth and branches bifurcated with notes, which grow in Hernandez’s native Costa Rica. “The ‘branches’ of our structure allow for the passing of the nutrients, and the farming modules are like the leaves of this tree,” Hernandez says. “We’re trying to mimic how nature produces food.”

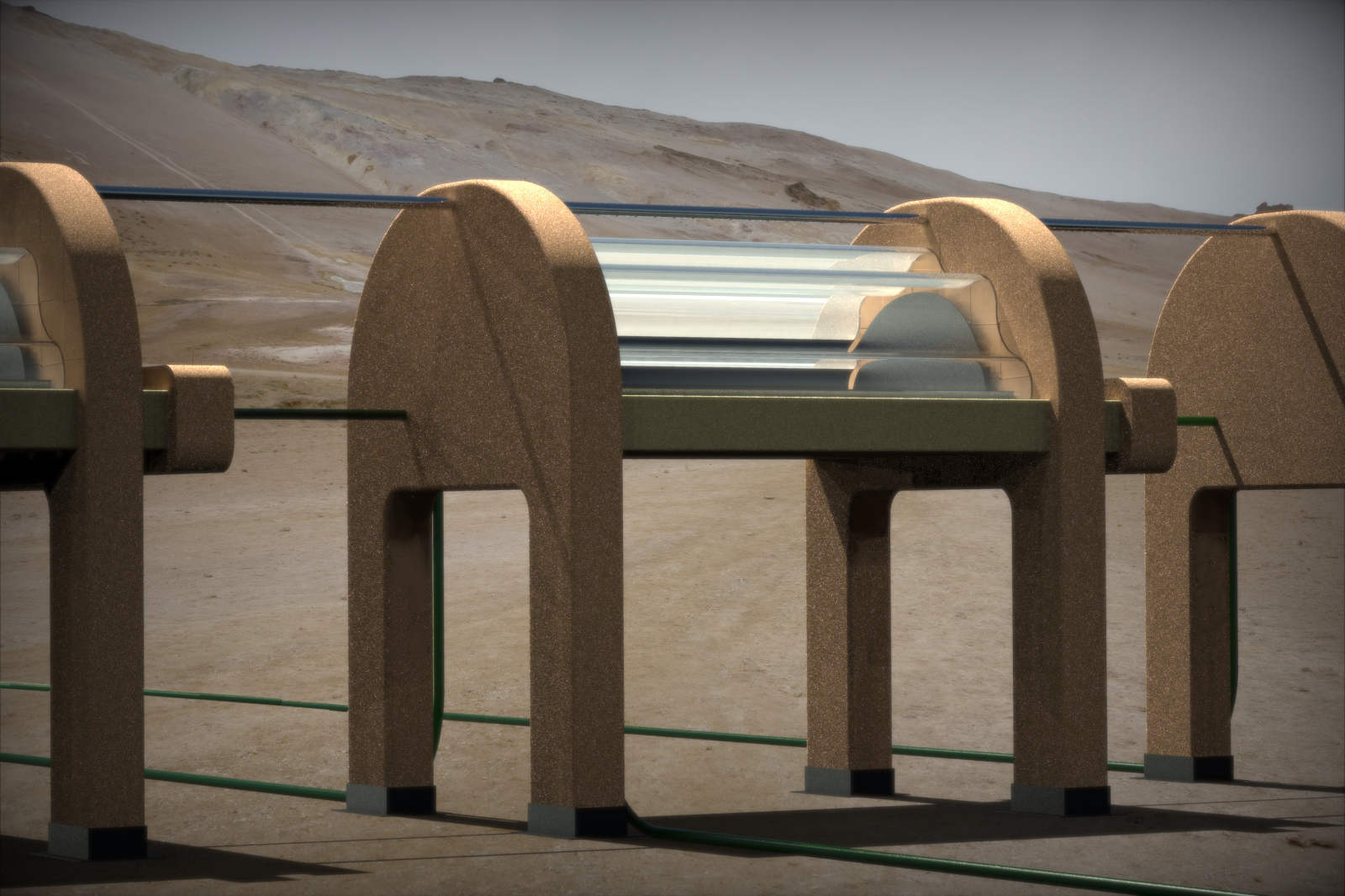

Mangrove Still: Impoverished, agriculture-dependent populations are most affected by climate change’s attendant land degradation and water scarcity. Environmental engineer Alessandro Bianciardi of Brescia, Italy, along with his team of designers, biologists, and business developers, sought to regenerate soil in the world’s drylands, rendering them more fit for agriculture. He looked to coastal ecosystems, such as mangroves and salt marshes. “In many drylands, freshwater is scarce but there’s an abundance of saline lakes, saline groundwater, and coastal water,” Bianciardi says. By mimicking coastal plants’ ways of managing water resources in a salty-water environment, his team created a low-cost, desalinating solar still that evaporates salty water, condensing it into still water that can be used for agricultural purposes. “The process of desalination is usually too expensive for irrigation and used only for drinking water,” Bianciardi says. “The idea is that the freshwater eventually enhances soil texture, which attracts moisture and allows other plants to thrive. It’s a cascade process.”

Bianciardi and his team designed the mangrove still for NGOs involved in combating hunger and restoring land in developing countries, and they plan to do some pilot testing in Tanzania and Namibia within the year. But considering the coming mega drought, its reach could conceivably be limitless. “The mangrove still could certainly support agriculture in drought-affected places like California and Australia, too,” Bianciardi says.

Photo courtesy of Biocultivator

Biocultivator: A Texas horned lizard might not seem like the obvious source of inspiration for a team of eco-designers from Zvolen, Slovakia. Zuzana Toncikova and Frantisek Toth, however, were fascinated by the creature’s ability to collect water on its body surface and thus survive in arid climates. They studied such mechanisms and emerged with the Biocultivator, a self-sustaining system that attracts moisture, helping busy city dwellers to effortlessly grow their own organic food, right on their balconies. A cupola up top collects moisture from rain and humidity, and on the bottom, users’ own recycled organic waste, a compost system, provides plants with nutrients. “The system also recycles moisture from the compost,” explains Toncikova.

Biocultivator’s inspiration also stemmed from Toncikova’s frustration with supermarkets. “It’s hard to trust that food is 100 percent organic,” she says. “In this device, you’re able to produce your own fertile soil and organic fertilizer—you know what goes inside.” What’s more, the cupola comes equipped with the solar cells needed to produce their own electricity, and users can use their smartphones to check on the status of their systems—and contribute information to other Biocultivator users. “We hope to collect and provide users with data about, say, which plants grow well together and what’s better on the sunny versus north-facing balconies,” Toth says, explaining that they have a partner in Slovakia developing an accompanying app.

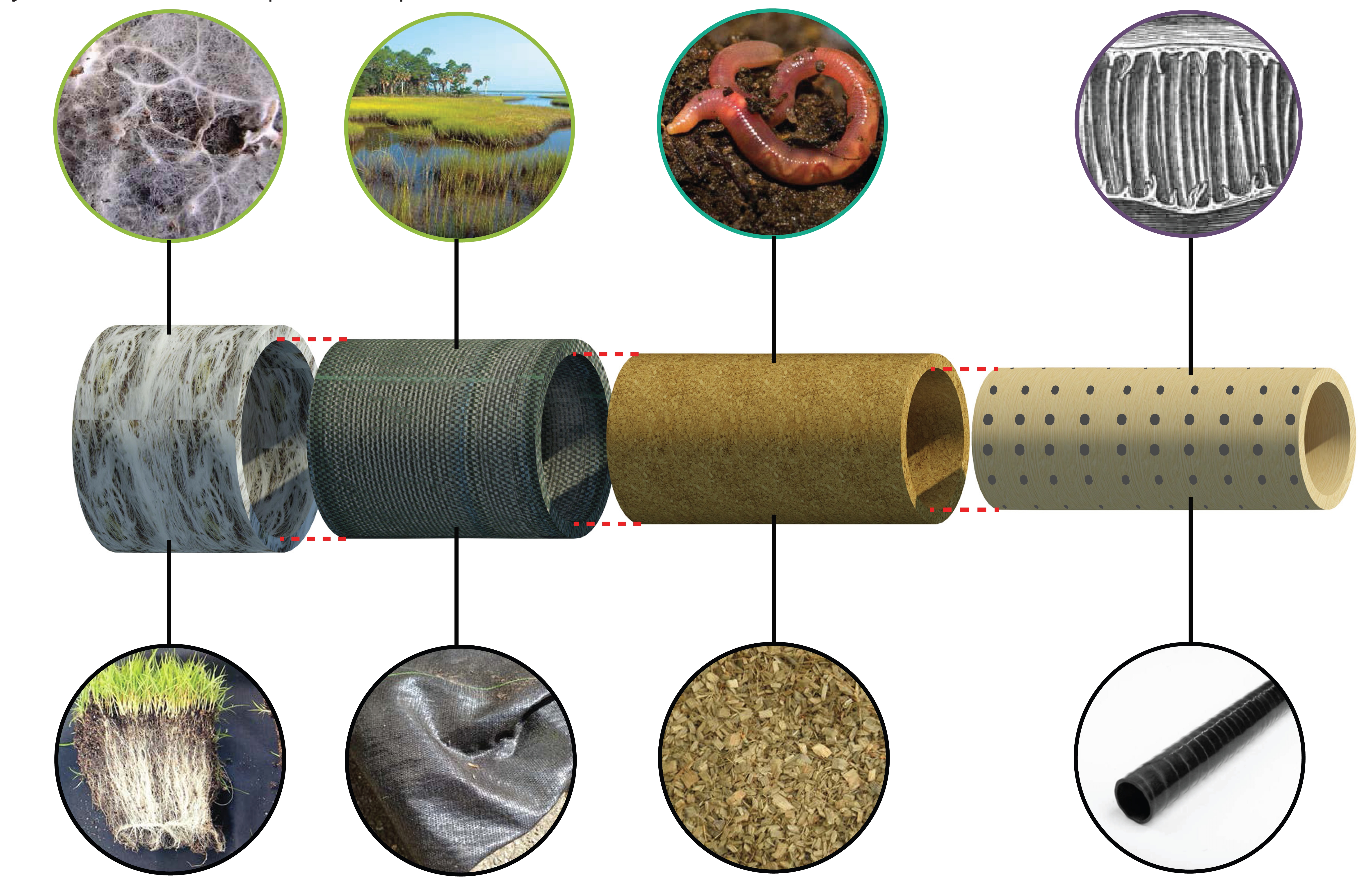

Photo courtesy of Living Filtration System

Living Filtration System: The problem with agricultural drainage systems is that they often deplete farm fields of nutrients and cause excess fertilizer runoff. So, some landscape architecture graduate students at the University of Oregon looked to other systems, eventually settling on the model of digestive ones. “An earthworm’s digestive system—a tube within a tube—inspired our form,” says team member Allison Lewis, explaining that the Living Filtration System involves a pipe that’s really a series of nested parts. Adds her former classmate Matt Jorgenson (they’ve now graduated), “We also looked at humans’ small intestines, specifically the villi, those little finger-like projections that line it, aiding absorption.” He explains, “This is where all the absorption happens, and villi also help increase intestines’ surface area. We wanted to increase our pipe’s surface area to slow the water down and capture the nutrients before they leave farm fields.”

The objective is to decrease the amount of fertilizer farmers need to use and to improve soil health over time. “Our target audience is government agencies looking to find ways to address polluted runoff from farm fields at the point of source,” explains Lewis. “A lot of money and effort goes into cleaning runoff once it’s accumulated downstream and is headed for larger bodies of water.”

Already on their third round of prototyping, the team has piqued the interest of a Portland, Oregon, nonprofit and is planning a large-scale field test. “Our biggest challenge is convincing farmers that the change is necessary and affordable,” says Jorgenson. “As we move forward, we’ll partner with farmers so we can share resources with them, and so they don’t lose money during the transition.”

Photo courtesy of Jube

Jube: A team of four Thai undergraduates dazzled judges with the function and beauty of their bio-inspired chamber for capturing edible insects and nabbed a $15,000 third-place prize. Team Jube member Pat Pataranutaporn says they were inspired by UN reports describing insects such as crickets and grasshoppers as “the protein of the future.” They studied the physicality of carnivorous plants, modeling the chamber of their device accordingly. Made from dry leaves and other natural materials, users simply fill the chambers’ natural bases and wait for them to fill with free, protein-dense food. Aesthetics were important, Pataranutaporn says, because of the “yuck factor.” To that end, the team’s side project involves using a 3-D printer to print cookies in the shapes of insects “so people can get used to bugs.” He adds, “We’re working on a patent for that.”

Photo courtesy of Oasis Aquaponic System

Oasis Aquaponic System: This solution to help subsistence farmers grow more food using less space, less water, and no chemicals fetched a $20,000 second-place prize. It all started when Michelle Leach, who says she got into biomimicry by “falling through a hole in Google,” traveled from her home state of Michigan to Central America on a volunteer trip just as she was finishing a PhD in biomedical engineering. She met Jacquelyn Smith Hernandez Ortiz, who was finishing a B.A. in agricultural engineering. The two started a conversation about aquaponics, a system of aquaculture in which waste produced by farmed fish or other aquatic animals supplies nutrients for plants to grow hydroponically.

Aquaponics’s symbiotic fish/water support system allows more food to be grown in a smaller area. Leach and Ortiz went to work refining the design of a small, low-cost, easy-to-manufacture system that could be used in rural Central America among other places. “We wanted to augment nutrition in food-insecure places and supply extra produce users could sell,” Leach says.

Their resulting, solar-powered aquaponics system—named the Oasis because it mimics a natural river flood plain’s ecosystem—is made from flexible plastic (most aquaponics systems are brick or cement), fits 200 fish, and is equipped to produce 200 pounds per year of vegetables. Leach and Ortiz recently received funding from an Indian NGO and will be piloting the system in Southeast Asia.

Photo courtesy of BioNurse

BioNurse: Camila Gratacos and Camila Hernandez, from The Ceres Regional Center for Fruit and Vegetable Innovation in Chile, took home the grand prize for their biodegradable soil restoration innovation. “Team BioNurse” found inspiration in hardy "nurse" plants, like Chile’s flowering yareta, which establish themselves in degraded soils and pave the way for new plant species to grow.

BioNurse won for its biodegradable BioPatch design. A low-cost product made from corn stalks (typically burned after harvest), the BioPatch can be placed over soil to enhance its capacity to retain water, nutrients, and microorganisms. BioNurse’s inspiration started in the Andes mountains, where Gratacos and Hernandez studied "cushion" plants, or those that nurse smaller plants underneath, providing nutrients and protecting them against wind, extreme temperatures, and UV rays. “They’re great for increasing biodiversity in monocultures,” Gratacos adds, referring to spaces in which only one species thrives. “All the plants in monocultures compete for the same minerals and nutrients and get weak. Incorporating biodiversity restores the vitality of crops.”

The BioPatch is available in five different patterns and is intended for commercial farmers trying to make the transition to sustainable agriculture. “They often don’t want to use chemicals anymore but don’t necessarily know how to switch,” Hernandez says.

Upon presenting Team BioNurse with the grand prize, Lanier said, “This design shows a true commitment to biomimicry, balanced with the greatest potential, we believe, to impact our food system’s challenges.”

The next round of the Global Design Challenge has just launched, meaning enterprising biomimics have another opportunity to compete for the $100,000 Ray of Hope Prize. This year’s challenge? Climate Change: Reversal, Adaptation, and Mitigation. Learn more here.

The Magazine of The Sierra Club

The Magazine of The Sierra Club